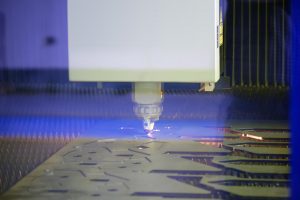

2D LASER CUTTING

High precision automated cutting process, which is used for manufacturing components that require forms, cuts, and angles demanding accuracy and precision.

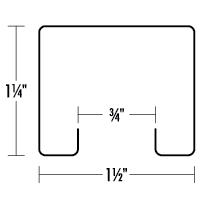

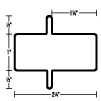

PURLIN PERFORATION

Purlins with tailor-made perforations that adjust to your project needs and reduce installation time and costs.

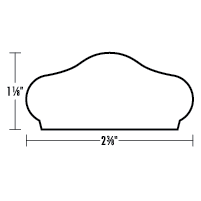

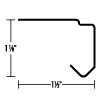

CNC BENDING CURTAIN

Equipment able to confront the most complex bending process with high quality, allowing a perfect assembly in any type of components.

FLOW DRILLING

Carbide and tungsten pointed drill used to make holes in metals, in which the material is pushed out with the help of friction heat, providing a fixing alternative of the traditional methods.

LASER TUBE CUTTING

Our laser cutting equipment allows us to make cuts and perforations with a very high degree of complexity and precision. Its application is ideal when accuracy is crucial.

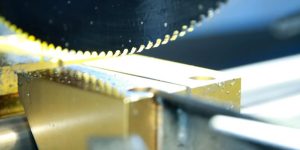

MITER SAW

State of-the-art equipment that allows to make high precision cuts at a very low cost. These machines can produce 90°, 60° and 45° cuts at very tight tolerances.

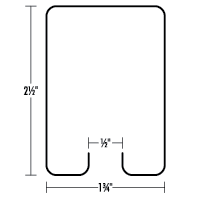

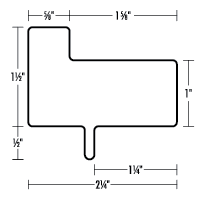

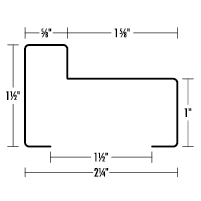

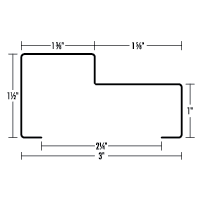

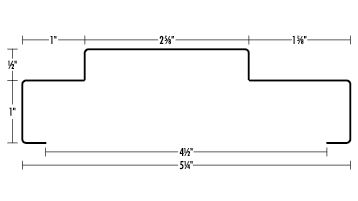

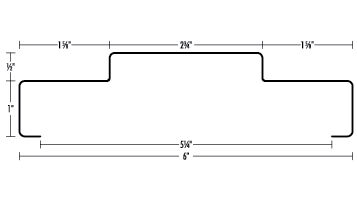

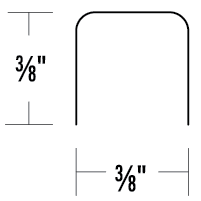

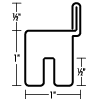

PRE-PUNCHED ROLL FORMING

Mill that offers any profile design to satisfy the client’s needs, including perforation patterns on specialized steel with tensile strengths of up to 1500 MP.

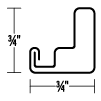

PUNCHING PRESS BREAK

Drilling, bending, punching, compression or any other solution requested by our customers.

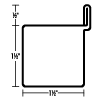

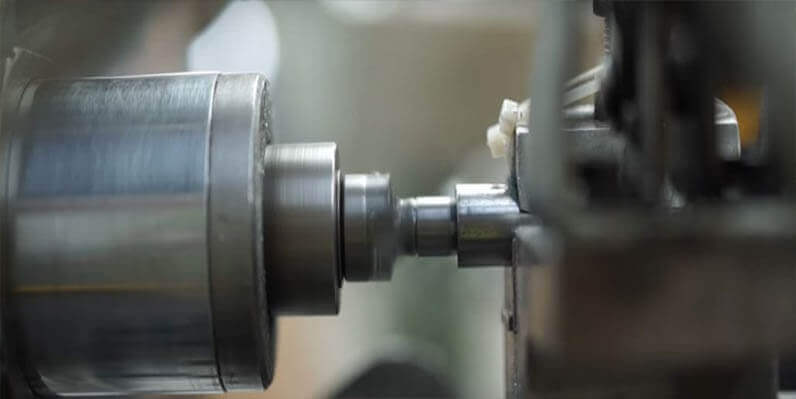

REAMING AND CHAMFERING

Internal and external processes to calibrate the tube’s thickness. It is used when high precision tube’s thickness is required, where component assembly needs to be exact.

Internal and external processes to calibrate the tube’s thickness. It is used when high precision tube’s thickness is required, where component assembly needs to be exact.

SECTION ROLLING

Equipment that allows to roll square, rectangular and round tubes in precise patterns controlled by high-end software.

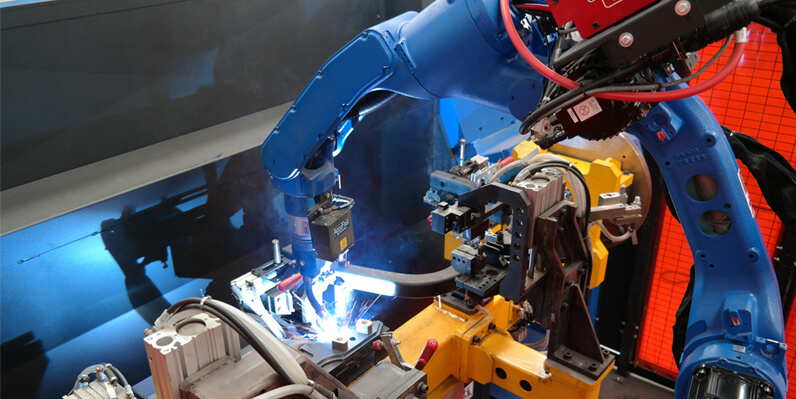

WELDING CELLS

Welding robots improve weld accuracy, torch access, and uptime. Long/extended articulated arm offers superior performance and extended reach.